Choosing a manufacturer to build your products is a critical decision. Finding the right match can be a daunting task for any business. You have to factor in the cost, speed, quality, and manufacturing processes before committing any production resources.

Partnering with prototyping companies should be a seamless experience once you know what to look out for. If you are looking around for a manufacturer to bring your prototype design to life, here are some factors to consider.

1. Industry Familiarity

The best prototyping companies have a portfolio you can use to review their past work. This information is essential to determine if they have handled similar projects before and specialize in the types of prototypes you need.

During this initial phase of product development, you need a company that’s experienced in your industry. They have better knowledge of materials to use, machines that can be used for the final product, and understand your industry language.

Working with such prototyping companies will make the manufacturing process much easier.

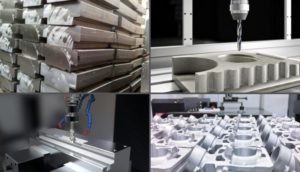

2. Prototyping Technologies

The prototyping company of your choice should also be up to speed with the technology changes. There’s more demand for complex prototype designs which need state-of-the-art technologies.

The best prototyping companies in the market invest heavily in technologies that enhance their product development processes. Therefore, if you work with such a company, you are assured of quality prototypes.

3. Manufacturing Capacity

Production capacity is essential for the business. Once you launch a prototype, you need to sustain orders that come after that within the given delivery time. The only way to support this is to choose prototyping companies that can handle and deliver large orders, even after the prototyping phase.

Before settling on a specific company or manufacturer, do your due diligence to ensure that the company can handle your type of business. This will save costs on trials and errors and also time spent looking for a new manufacturer once you get the big order on your product.

4. Speed

Prototypes need to be launched in the market much faster to get ahead of the competition. Therefore, you should only go for a company that has a qualified team of engineers and designers who can work quickly and get the prototypes out to the market fast enough.

This requirement is very critical if you want to gain an edge in the market. The top rapid prototyping companies rely on their advanced technologies to churn out prototypes in a few days. Therefore, if your prototyping company doesn’t meet deadlines, it’s better to look for another manufacturer.

Ask yourself whether the company has the speed to respond to quick-turn orders during product development, market launch, or production phase.

5. Prototyping Capabilities

The best prototyping companies should be able to handle all prototyping under one roof. So whether you want CNC machining, 3D printing, rapid tooling, or plastic injection molding, you should get all these from one supplier.

Partnering with a single, reliable prototyping company makes your work easier. You can source all the prototype components from one place and not have the pressure of coordinating orders from multiple prototyping companies. When the assembly of your prototype is handled by one company, you can easily coordinate changes by dealing with the same people.

In addition, prototypes require IP security. If more people from multiple companies see your design, it increases the chances of IP theft. However, when working with one provider, you have more security and can safeguard your unique prototype design until you launch into the market.

6. Quality Assurance

Quality assurance is essential in any manufacturing process. Working with companies that build product prototypes should come with high levels of quality. A manufacturer that focuses on quality assurance is less likely to produce defective components or parts. A good company will conduct quality assurance tests at each stage of the production cycle.

This process should not only be done at the end of the production process. It should also be backed by certification and documentation that certifies that the prototypes have been developed with the right materials and procedures.

7. Design Support

If you are an entrepreneur or this is the first time you are working with prototyping companies, you may not be an expert on most manufacturing processes. Therefore, before choosing a manufacturing partner, you should make sure they provide constant feedback and advice.

A good prototyping company should always offer you input, advice, and options available regarding the best materials to use and choosing the right process. Therefore, if you are not sure which processes to use, there’s nothing wrong with asking for advice from the company.

8. Service Cost

You should be able to afford the prototype company costs. The best prototype companies should list all the expenses for the entire project beforehand. This allows the customers to assess their budget and determine whether they can afford the manufacturing costs. Also, it’s much easier to manage the expenses if you are working with a single company.

9. Response Time and Communication

During the product development phase, it’s essential to get constant updates on the process so far. Once you contact the prototype companies for a quote, check how long they take to give feedback. Their response time is a pointer of how much time they’ll take to respond to you during the actual production phase.

It’s better to work with a company that responds to the customers fast.

10. ISO certification

ISO certifications and compliance standards are vital in the engineering and manufacturing sectors. Prototyping companies that are certified have passed an audit by an independent body because they exceed the set standards and higher quality assurance.

Choose a company that’s ISO-compliant to get better quality prototypes.

Summary

Prototyping companies bring your design idea to life. However, selecting the right company could make a difference in how much time and money you spend on the entire production process. Therefore, before settling on one manufacturer, you need to do your due diligence to confirm that they meet the above standards.

If you are looking for the best prototyping services for your products, contact us at WayKen. We will turn your ideas into reality with our quality manufacturing processes.

The post The Ultimate Guide to Select Prototyping Companies appeared first on Tweak Your Biz.

No comments:

Post a Comment